Automated Central Sterile Supply Department

Back in 2011, Gibotech introduced robotics into the sterile workflow of hospitals. We did this with an automated Central Sterile Supply Department, CSSD, which in several different ways helps to streamline and optimize the workflows in the hospitals. We are proud to have created the first intelligent CSSD in the world, which is responsible for automatically sterilizing the hospital’s instruments and operating equipment at Rigshospitalet in Copenhagen. This CSSD is a fully automatic solution in a class of its kind, which is expected to set the standard for future sterile centers both here in Denmark and abroad.

With a fully automatic Central Sterile Supply Department, it is possible to ensure that the sterilization of instruments and operating equipment is carried out correctly so that hygiene is in order. An automated CSSD will provide a quality-assured work process, as the actual work on sterilization takes place through a uniform, high-standard work process, thereby greatly improving the actual hygiene of infection.

A unique Central Sterile Supply Department

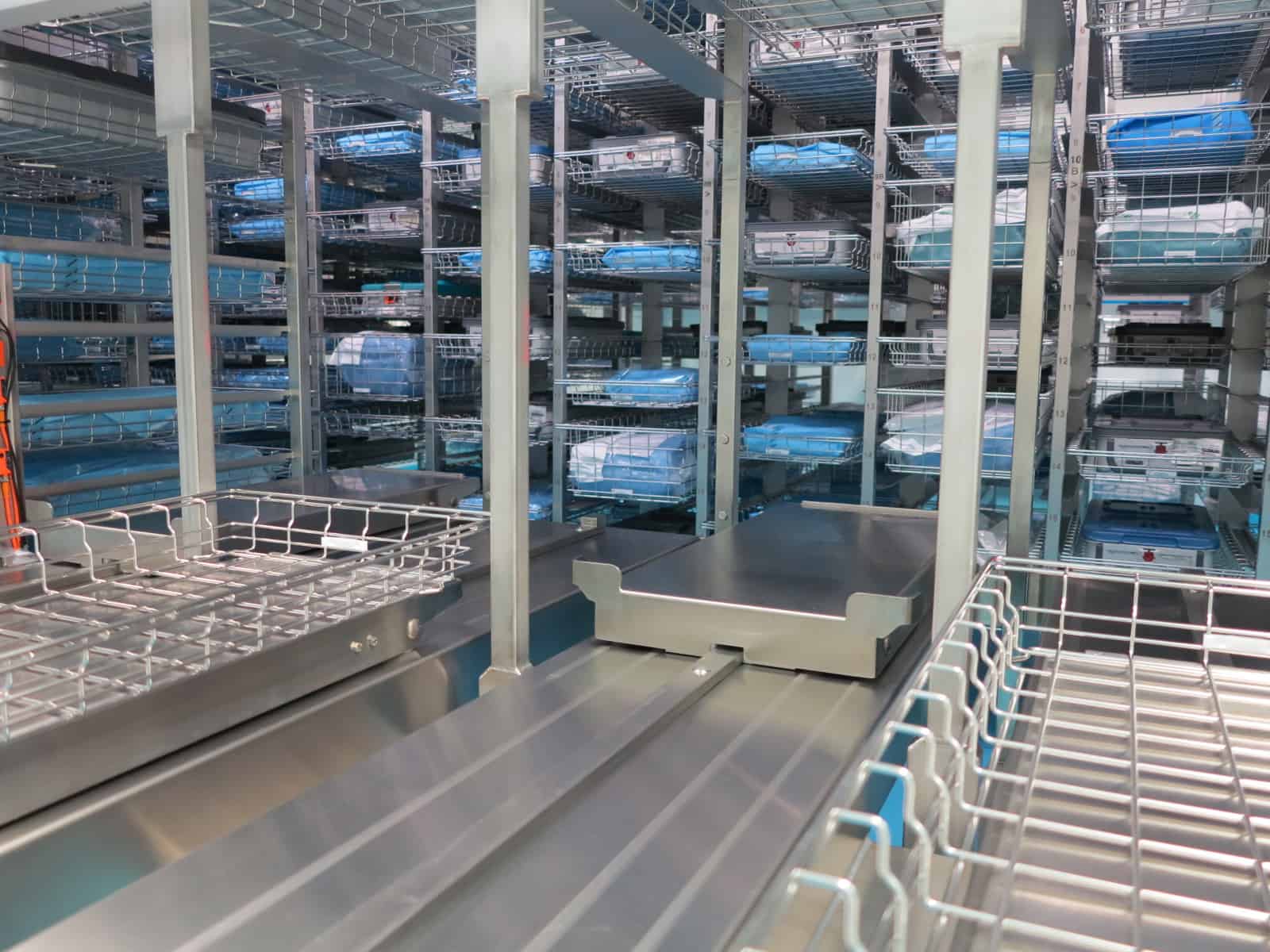

A Central Sterile Supply Department involves the use of robots and a conveyor belt, as well as a fully automated sterile warehouse. This means that from the moment the surgical instruments arrive at the CSSD from the operating departments until each instrument tray is packed and sterilized, the work will be supported by robots and assembly lines. At the CSSD, robots and conveyor belts will perform the physical lifting when the equipment is to be unpacked and packed in transport wagons.

The Central Sterile Supply Department is also made with a storage system that can ensure that the surgical containers are put away and that the transport wagons are packed with the instruments needed for each operation. In this way, the number of handlings is reduced, minimizing the risk of work injuries in employees and extending the sterility life of the instruments that have been handled by CSSD, as there are fewer hands coming into contact with the instruments and trays. The CSSD will streamline the work of washing, packing and autoclaves the surgical instruments, and it can service all departments, outpatient clinics and operating departments in the hospital.

At Gibotech, we create tailor-made solutions for the individual customer, and an automated CSSD can thus be established in completely new buildings and can be adapted to the requirements of already existing buildings. With a CSSD, time is released by employees for clinical and patient-related tasks. In Denmark, there are strict requirements for the working environment, but this should not be considered in an automated CSSD, which can be placed in environments where people are not allowed to work. Since our robot solutions are based on modules, it is possible to adapt the CSSD to suit the specific needs and capacity of each hospital.

At Gibotech, we can offer several different kinds of robotics that can help optimize the sterile workflow in hospitals. In addition to the high-tech CSSD, we have also developed various storage systems that ensure easy and efficient product reception and handling, just as Gibotech is behind various solutions for handling blood samples in hospitals. As long as the machines are in operation, we can also offer to enter into an agreement for robot service, which also applies in the evening hours as well as on weekends.

Efficient inventory management with an automated Central Sterile Supply Department

Automatic hospital logistics facilitates the work of the employees. A Central Sterile Supply Department can be made so that the individual employee can log in and the table automatically adjusts to its height so that the working position is optimal. In this way, the ergonomic conditions of the employees are improved, which in turn can reduce the number of injuries and sick leave in the workplace.

Automation enables technology to monitor and control the production and delivery of products and services. Automation has many advantages and can benefit both healthcare and businesses. At Gibotech, we develop industrial robots that allow us to make full use of the production facility and improve competitiveness. Robots can work 24 hours a day and do not need holidays and sick days, and automated solutions can thus help improve production capacity both during normal working hours and outside.

Whether we are developing hospital robots or industrial robots,we do so in close cooperation with the customer and based on thorough analysis to ensure that we meet the specific needs. We have many years of experience with automation solutions, and it is precisely this experience that we draw on when developing new solutions for our customers in the industry and hospital sector.

There are several good reasons why automatic hospital logistics is an investment that benefits employees as well as patients in both the short and long term. The automated work processes will reduce the number of human tasks that naturally minimize the risk of human error. Automatic hospital logistics also restricts unilateral and repetitive work, just as a Central Sterile Supply Department ensures that the heavy lifting is handled by robots and conveyor belts, and this could therefore improve the ergonomic conditions for the employees at the hospital. If you want to know more about the many benefits associated with a sterile center, you are welcome to contact us.

The first in the world

Gibotech installed the first sterilization central at Køge Hospital in 2011. In 2018, Rigshospitalet and Herlev Hospital will follow.

Scalable

Gibotech’s solutions are modular and scalable and can, therefore, be adjusted for the hospitals’ individual demands and requests.

Improved working environment

Monotonous and repeating tasks are minimized and the risk of work-related injuries is reduced. The staff will have less sick days.

Increased patient safety

Fewer manual work routines minimize the risk of errors and increase patient safety significantly.

Increased quality Fewer manual tasks provide a higher quality and reliable results with 100 % traceability, and the employees have more time for clinical, quality, and patient-focused tasks.

Satisfied employees An automatic sterilization central will improve employees work routines significantly. The concept is based on the overall automation of most of the heavy and repeating tasks, by replacing the manual processes with robots, mobile robots, and conveyor systems.

It is an amazing opportunity for us to test the robotic solutions in our current hospital. It gives us a technological advantage for 2020 when we are moving into our new super-hospital. The experience that we gain will be tremendous for us when we develop our high-tech laboratory in the new hospital, while also ensuring the absolute best in terms of patient safety today.

Efficient storage control By automating the control of the sterile storage, the hospitals require less space for storage of surgical instruments. The inventory robot supports the control of and compliance with expiration dates and first in, first out principle, which result in a more even distribution of the sterile instruments.

Optimal use of buildings An automatic sterilization central can be installed in new buildings, or adjusted to fit the requirements in existing buildings. The robots are flexible and have fewer demands for the physical work environment than employees, which make it possible to place them in less attractive rooms like the basement.

years of experience

Scalable robotics cells

Brands that can supply these solutions

Contact us

The more information you provide, the quicker we can provide the right department with your query.

Send message