GiboSmartSolutions

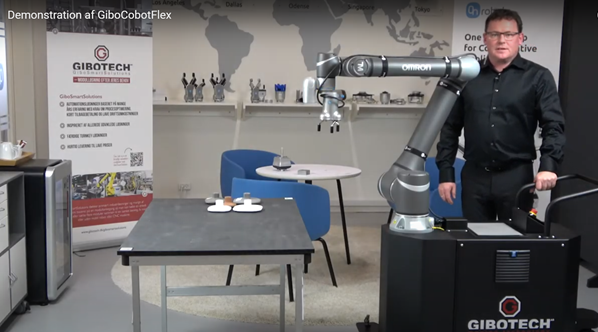

GiboCobotFlex

GiboCobotFlex meets all needs and requirements for flexible production with a cobot and is designed so the robot and cart stays the same, but the equipment defines the task. It’s easy to get started and you can always expand with more EoAT to match specific requirements.

Robot

Omron TM 12/14,

FANUC CRX 10/10L

Gripper

OnRobot, Schunk, Gimatic

Jobs

All jobs where cobots are the obvious choice and flexibility is a must

Solution

May be combined with Omron AMR or integrated towards a third party AGV

Delivery

Max 3 months

Advantages

- Flexible solution based on standard components

- Expandable to meet all requirements

- Mobile and easily converted for other jobs

- Short delivery time

- Value for money

- Short ROI

- Easy to use

Solution

• Robot incl. controller

• Standard gripper

• Transport cart robot with integrated electrical cabinet

• 3 day programming course and commissioning

• 2 day training course in risk assessment

Add ons:

• Omron LD AMR (Autonomous Mobile Robot)

• Telescopic socket

• Floor fixture brackets

• Omron PLC when prescription management is needed

• Grippers/EoAT fom Schunk, OnRobot or Gimatic

• Grinding and polishing tools

• Assememby

• Mobile 4 wheel cart

• Hole plate fot items

• Pallet guides

• Create station

• Ribbon lanes

• Box erector incl. gripper for boxes

• Integration towards other machines

• Safety scanners, light curtain or physical fence

Functionality

GiboCobotFlex combines the cobot’s easily accessible programming with high flexibility and applications that provide the foundation for maximum utilization and operation creating optimal ROI.

GiboCobotFlex is designed to cover a wide range of tasks from machine tending and assembly to palletizing etc. The core of the solution lies in the mobile socket that can be moved from task to task. The base itself is moved to the task and the suitable equipment for the specific task is attached on the side. This is done easily by placing the equipment as close as possible to the socket. Then the robot detects the precise position via a landmark placed on the side equipment.

To achieve maximum flexibility, the EoAT is based on standard grippers based on the Plug-and-Play principle. This means thatGiboCobotFlex can operate a CNC machine one day and the next day it may palletize boxes on euro pallets or polish items.

The entire solution is bound together by user-friendly drag-and-drop programming in the included software.

The list of side equipment and grippers is continuously expanded and can be purchased as needed.